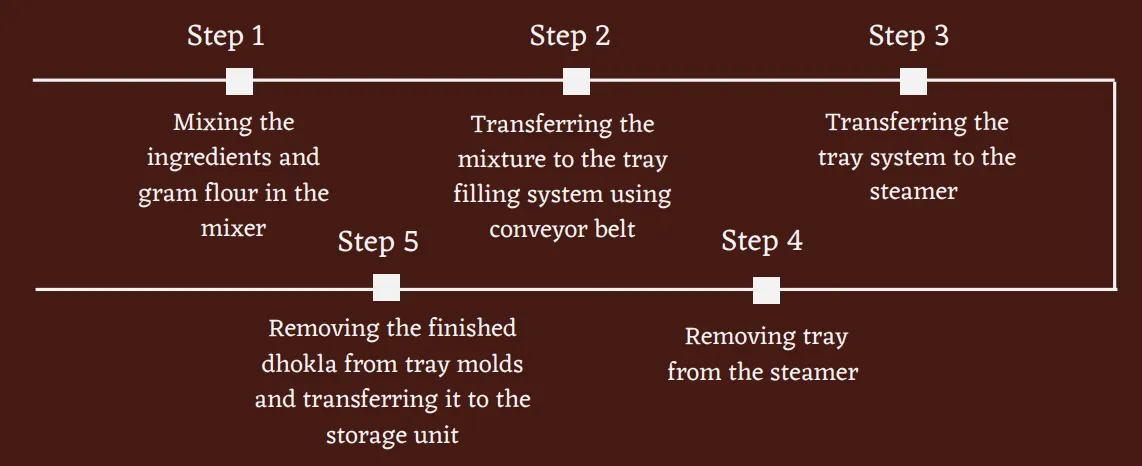

Process

Parameters Involved

- Estimate time to steam batter = 30 min

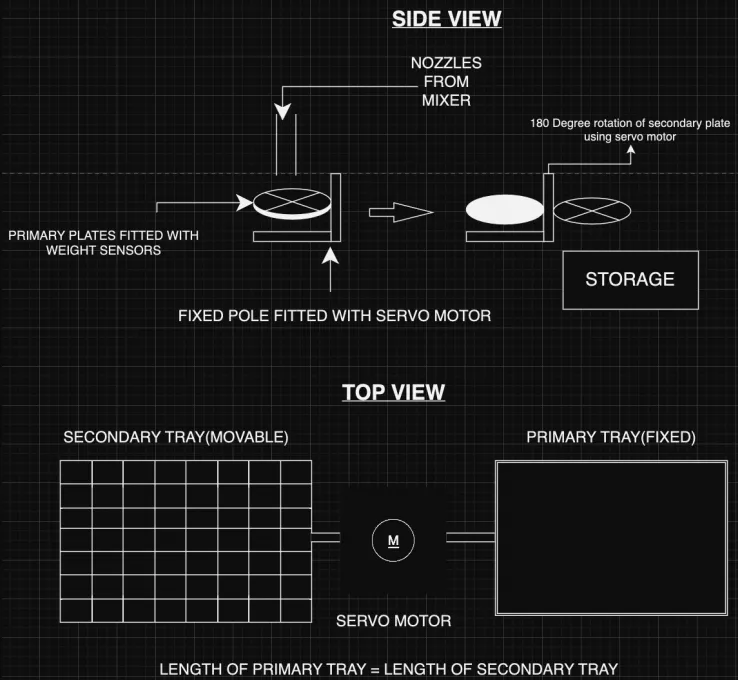

- Speed of conveyor belt = 1m/s

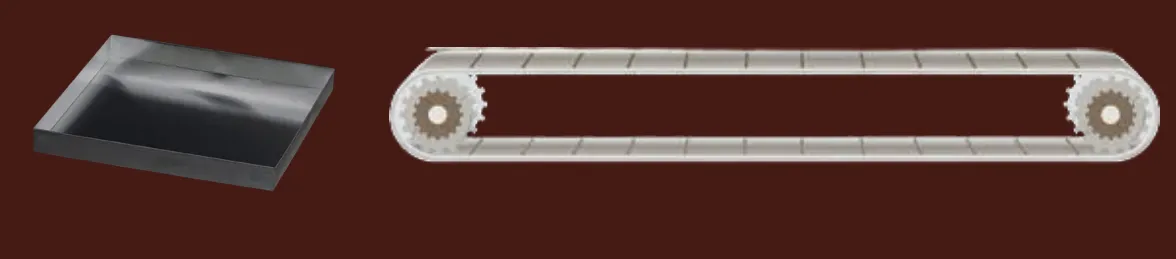

- Dimensions of mould plates for batter = 40cm40cm8cm (lbh)

Governing Equations

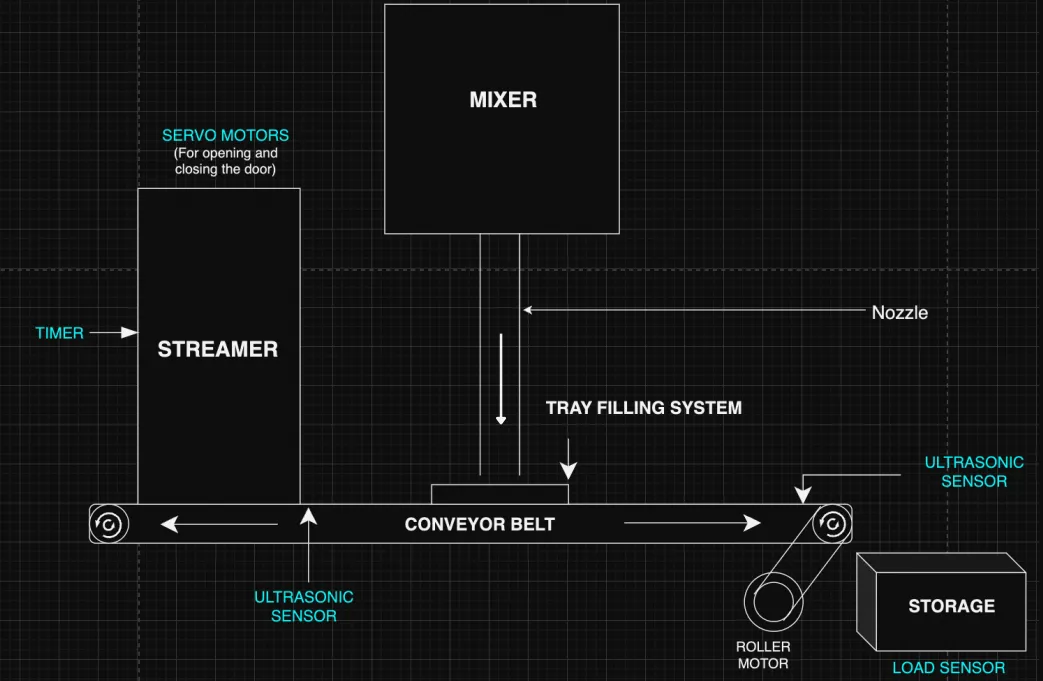

Conveyor Belt

-

Equation for length (L)

-

Equation for velocity (v):

Definitions:

- (D) = diameter of roller

- (c) = center-to-center distance (distance between centers of rollers)

- (L) = length of conveyor belt

- (v) = velocity of conveyor belt

- (a) = acceleration of conveyor belt

- (t) = time taken for moving the plate

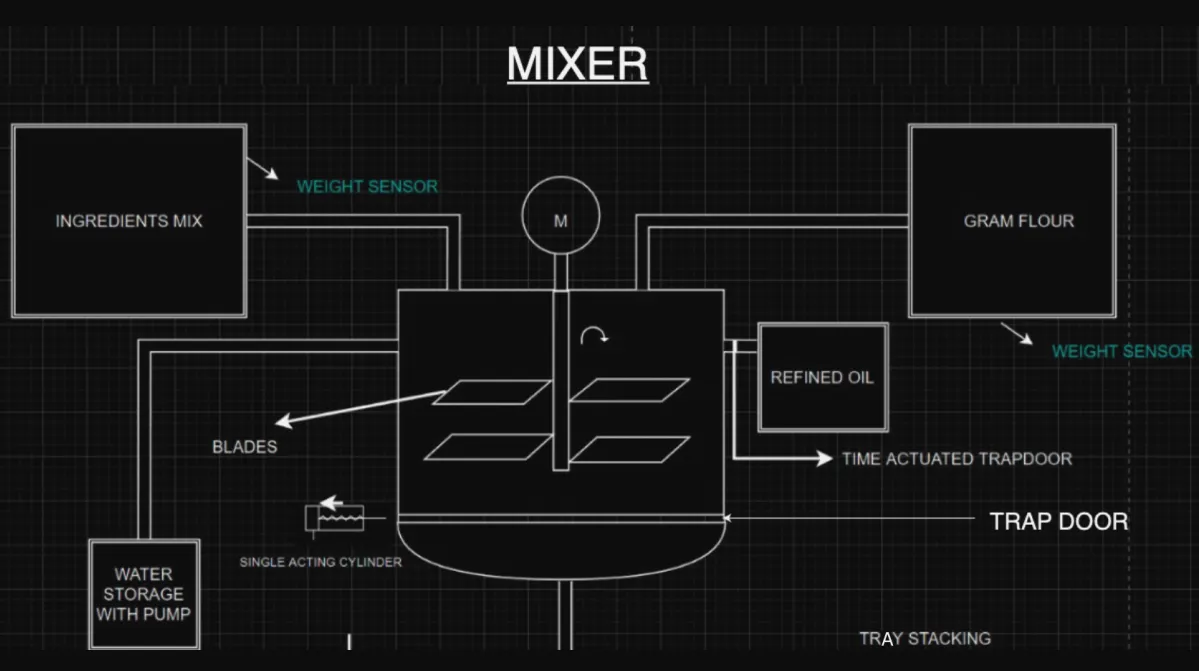

Mixer

-

Volume displaced per revolution (V_1)

-

Volume displaced per minute (V_2)

Definitions:

- (D) = blade diameter

- (H) = blade height

- (N) = number of blades

- (RPM) = revolutions per minute (shaft speed)

- (V_1) = volume displaced per revolution

- (V_2) = volume displaced per minute

- (G) = gallons displaced per minute

Steaming Equation

-

Heat energy ( Q )

Definitions:

- Q = quantity of energy or heat (kJ)

- m = mass of substance (kg)

- cp = specific heat of substance (kJ/kg °C) — material properties and heat capacities for common materials

- dT = temperature rise of substance (°C)

-

Heat transfer rate ( P )

Definitions:

- P = mean heat transfer rate or power (kW (kJ/s))

- m = mass of the product (kg)

- cp = specific heat of the product (kJ/kg °C) — material properties and heat capacities for common materials

- dT = change in temperature of the fluid (°C)

- t = total time over which the heating process occurs (seconds)

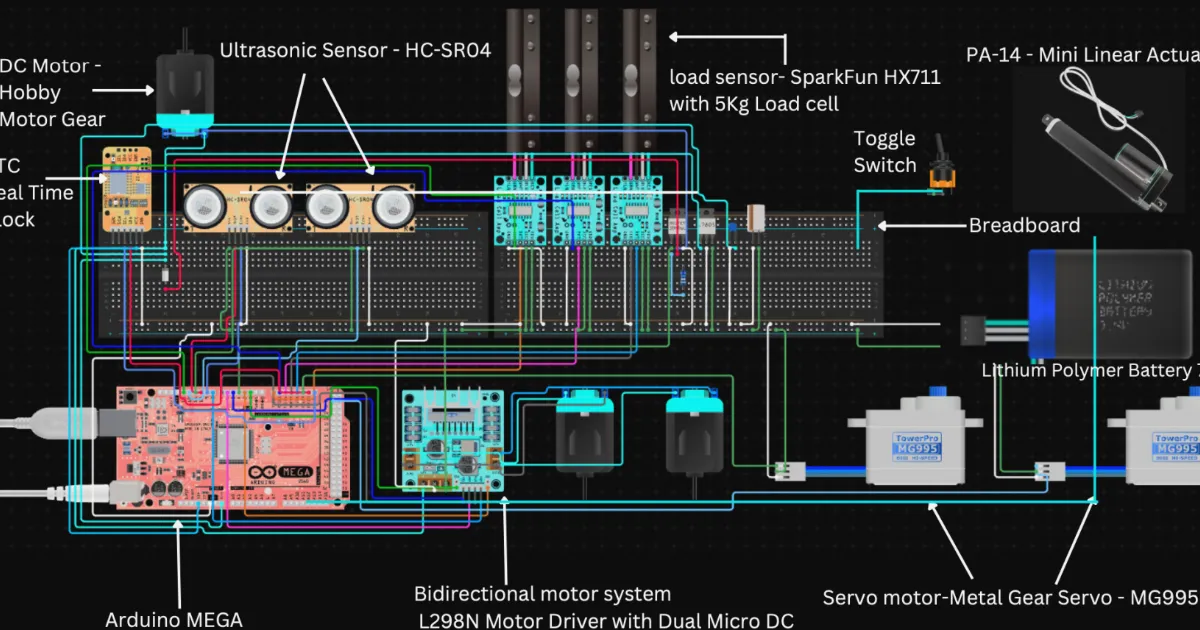

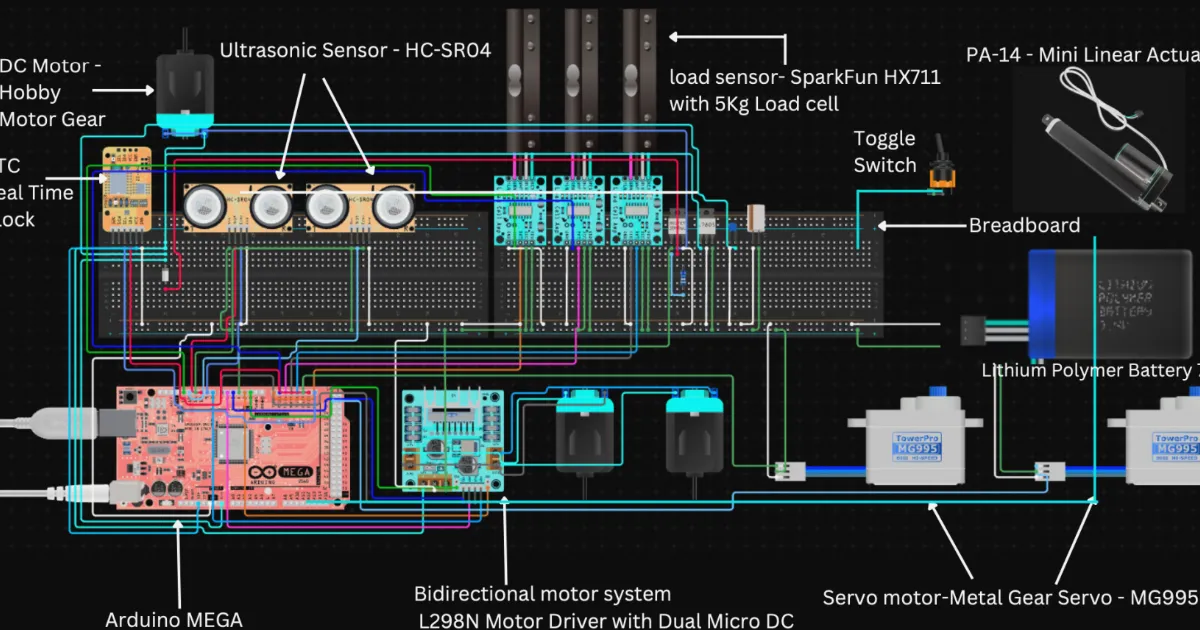

Components

- Load sensor - SparkFun HX711 with 5Kg Load cell

- Servo motor - Metal Gear Servo - MG995

- Servo motor - Metal Gear Servo - MG995

- L298N Motor Driver with Dual Micro DC Motors (Geared)

- Ultrasonic Sensor - HC-SR04

- PA-14 - Mini Linear Actuator

- Lithium Polymer Battery 7.4v

- DC Motor - Hobby Motor Gear

- RTC - Real Time Clock

- Breadboard

- Arduino MEGA

- Toggle Switch SPDT

Circuit

Design

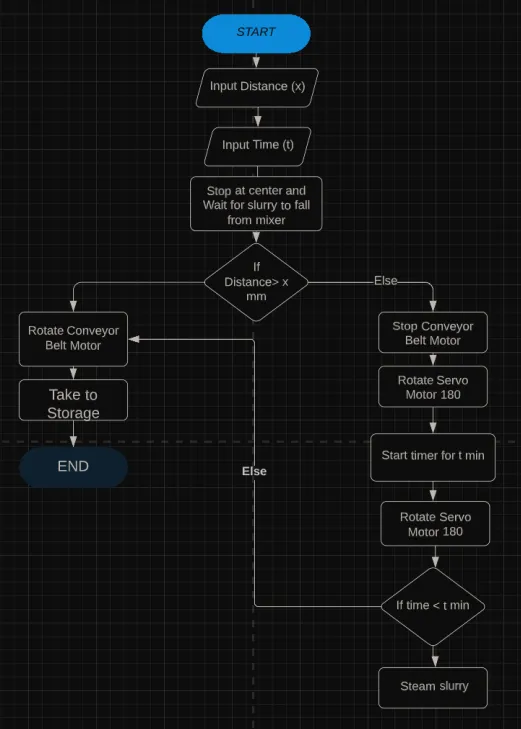

Algorithm

Code

#include "HX711.h"

#include <Servo.h>

#define calibration_factor -7050.0

#define loadcell_dout_pin x

#define loadcell_sck_pin y

HX711 scale;

Servo servo;

long duration;

float dist=11;

int motorPin =10;

int motor1pin1 = 1;

int motor1pin2 = 12;

int motor2pin1 = 2;

int motor2pin2 = 9;

int uss1Tpin = 3;

int uss1Epin = 4;

int uss2Tpin = 5;

int uss2Epin = 6;

int pos = 0;

int servoPin = 8;

// Dual motor move left

void dualMotorMoveLeft() {

digitalWrite(motor1pin1, HIGH);

digitalWrite(motor1pin2, LOW);

digitalWrite(motor2pin1, HIGH);

digitalWrite(motor2pin2, LOW);

}

// Dual motor move right

void dualMotorMoveRight() {

digitalWrite(motor1pin1, LOW);

digitalWrite(motor1pin2, HIGH);

digitalWrite(motor2pin1, LOW);

digitalWrite(motor2pin2, HIGH);

}

// Dual motor stop

void dualMotorStop() {

digitalWrite(motor1pin1, LOW);

digitalWrite(motor1pin2, LOW);

digitalWrite(motor2pin1, LOW);

digitalWrite(motor2pin2, LOW);

}

// Ultrasonic sensor function

void uss(int ussTpin, int ussEpin){

digitalWrite(ussTpin, LOW);

delayMicroseconds(5);

digitalWrite(ussTpin, HIGH);

delayMicroseconds(10);

digitalWrite(ussTpin, LOW);

duration=pulseIn(ussEpin,HIGH);

dist=duration/60;

delay(100);

}

// Servo open

void servopen(){

for (pos = 0; pos <= 180; pos += 1) {

myservo.write(pos);

delay(15);

}

}

// Servo close

void servclose(){

for (pos = 180; pos >= 0; pos -= 1) {

myservo.write(pos);

delay(15);

}

}

void setup() {

Serial.begin(9600);

Serial.println("Starting weight measurement");

scale.begin(loadcell_dout_pin, loadcell_sck_pin);

scale.set_scale(calibration_factor);

scale.tare();

pinMode(motorPin, OUTPUT);

pinMode(motor1pin1, OUTPUT);

pinMode(motor1pin2, OUTPUT);

pinMode(motor2pin1, OUTPUT);

pinMode(motor2pin2, OUTPUT);

pinMode(uss1Tpin, OUTPUT); // trigger pin in USS

pinMode(uss1Epin, INPUT); // echo pin in USS

servo.attach(servoPin); // servo motor pin

}

void loop() {

digitalWrite(motorPin,HIGH);

if(scale.get_units() > 12){

digitalWrite(motorPin, LOW);

Serial.println("Mixer blade has stopped, weight is reached.");

}

delay(3000);

Serial.println("Starting uss");

delay(1000);

dualMotorMoveLeft();

while(dist > 1000){

uss(uss1Tpin,uss1Epin); // moves the motor

}

dualMotorStop();

delay(1000);

servopen();

dualMotorMoveLeft();

while(dist > 500){

uss(uss1Tpin,uss1Epin);

}

dualMotorStop();

servclose();

Serial.println("Sweet is inside the steamer...");

delay(1800000); // steamer for 30 min

servopen();

dualMotorMoveRight();

while(dist > 100){

uss(uss2Tpin,uss2Epin);

}

dualMotorStop();

delay(10000);

}