Executive Summary

This was done during my time at Simpore.

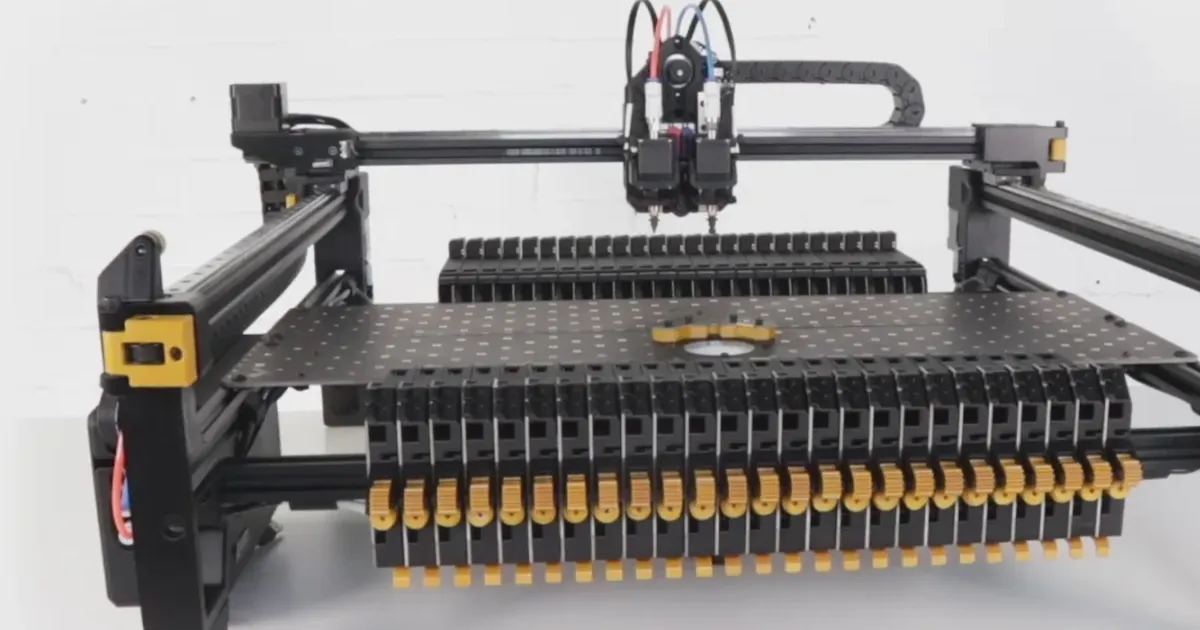

This project implements a compact, vision‑guided micro‑assembly and adhesive‑dispensing cell on top of OpenPnP (OpenCV‑powered) and the LumenPnP hardware stack. We retrofit one nozzle rotation stepper on the pick‑and‑place head to actuate a linear syringe plunger for UV‑curable adhesive, enabling a tightly orchestrated pick–place–dispense–cure workflow on a single platform. With calibrated optics, lighting, and stage mapping, the system achieves micron‑level socket detection and pose alignment to insert silicon shapes into plastic fittings, applying controlled adhesive volumes prior to UV exposure. A production‑grade data pipeline archives images and process metadata at each step and runs anomaly detection to flag misplacement, under/over‑dispense, and other defects. The result is a software‑defined manufacturing cell that improves first‑pass yield, reduces cycle time, and provides full traceability.

System Architecture

-

Motion platform: LumenPnP mechanics driven by OpenPnP kinematics, feeders, and macros.

-

Dispenser retrofit: Nozzle rotation stepper remapped to a linear syringe actuator; stroke, rate, and retract exposed via G‑code/macros; UV source triggered through IO.

-

Vision stack: OpenPnP pipelines with OpenCV filters for fiducial registration, sub‑pixel socket detection, and silicon pose estimation.

-

Calibration: Camera intrinsics/extrinsics, lens distortion removal, hand–eye mapping to stage coordinates; flat‑field lighting and exposure/color balance locks.

-

Process control: Recipes sequence pick heights, forces, adhesive volume/standoff, UV dose, and verification captures.

-

Data/QA: Image and metadata logging per unit; ML‑based anomaly detection for in‑line quality assurance and SPC.

Methodology

- Requirements and Targets

-

Define dimensional tolerances and Cp/Cpk goals for silicon‑to‑plastic fit.

-

Specify adhesive, UV wavelength/irradiance, cure dwell, and safety.

-

Establish cycle time/throughput targets and allowable rework rate.

- Mechanical Integration

-

Design linkage to couple the syringe plunger to the nozzle rotation stepper (or add a micro linear actuator).

-

Characterize backlash, compliance, and repeatability; measure force–displacement curves across viscosity/temperature.

-

Mount UV source with shielding; integrate interlocks and machine IO.

- Motion and Dispense Control

-

Map step/dir for the dispenser axis in OpenPnP; define soft limits and homing.

-

Implement macros for prime/purge, volumetric dispense, anti‑drip retract, and synchronized triggers with placement.

-

Calibrate volume vs. steps using gravimetry or image‑based volumetry; build compensation tables for temperature/viscosity.

- Vision Pipeline (OpenCV in OpenPnP)

-

Global alignment via fiducials; distortion‑corrected coordinates.

-

Socket detection using edge/contour segmentation and ellipse/circle fitting with sub‑pixel refinement.

-

Silicon shape pose via template matching/PCA with RANSAC outlier rejection.

-

Validate repeatability in microns using a dot‑plate or gauge artifact.

- Photometric and Geometric Calibration

-

Flat‑field correction and lighting uniformity maps; lock exposure/white balance.

-

Camera intrinsic/extrinsic calibration and hand–eye to tool center point (TCP).

-

Compensate head runout and dispenser tip parallax.

- Process Recipe Development

-

Parameters per SKU: pick height, approach speed, placement force/dwell; adhesive volume, dispense rate, standoff, path; UV intensity and time.

-

DoE to optimize spread vs. wicking vs. bond strength; set guard bands for ambient and adhesive age.

- Data Pipeline and Traceability

-

Store raw and annotated images at pre‑place, post‑place, pre‑cure, post‑cure checkpoints.

-

Log offsets, placement error, dispense steps/volume, UV dose, lot/operator IDs.

-

Provide dashboards for pass/fail, drift, and SPC charts.

- Anomaly Detection and ML QA

-

Rule‑based checks for alignment tolerances and area/coverage thresholds.

-

Train a lightweight classifier/segmenter (e.g., MobileNet/UNet) on archived images to detect under/over‑dispense, voids, contamination, skew.

-

Integrate inference as an asynchronous service; surface confidence and thumbnails for review and continuous improvement.

- Validation, SPC, and Maintenance

-

Gauge R&R for placement (µm) and dispense (nL); repeatability studies.

-

Control charts (X‑bar/R) for placement error, adhesive coverage, and cure defects; auto‑stop thresholds.

-

Maintenance: tip cleaning, syringe change, UV irradiance checks, periodic re‑calibration.

Outcomes and Benefits

-

Micron‑level alignment and consistent adhesive deposition through calibrated vision and compensated dispense control.

-

Rapid, software‑defined recipe changes for new geometries with minimal mechanical changeover.